News

The governing body of the Cambridge Harbor development, which has come under fire in recent weeks following the resignation of City Manager Tom Carroll, has posted two streaming links to its community update meeting Wednesday.

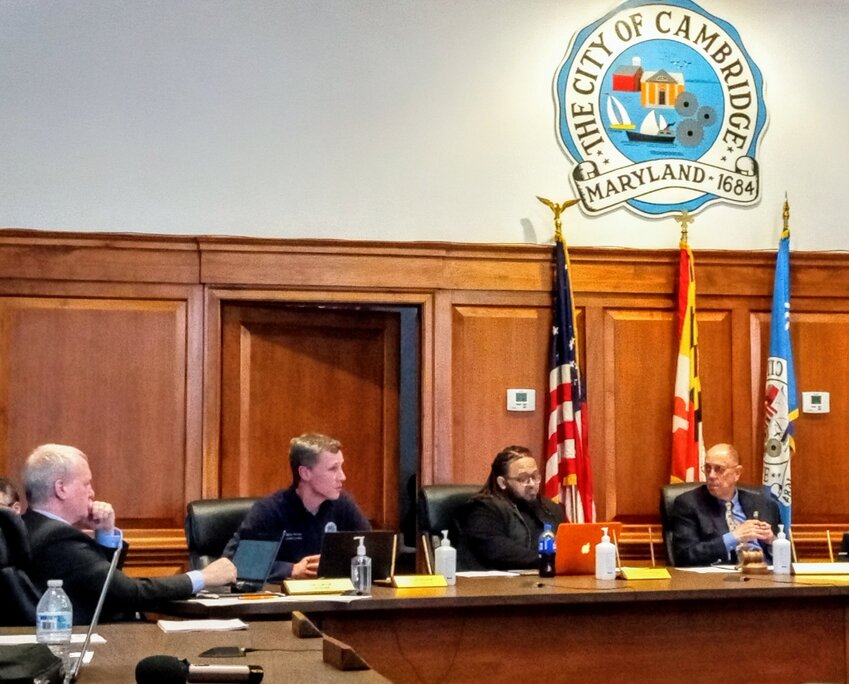

Cambridge Mayor Steve Rideout took steps to assert city oversight into Cambridge Harbor activities with the introduction of amended articles of incorporation for Cambridge Waterfront Development, Inc. (CWDI).

Under the revisions, the Mayor of Cambridge would be designated as the nonprofit CWDI’s sole member.

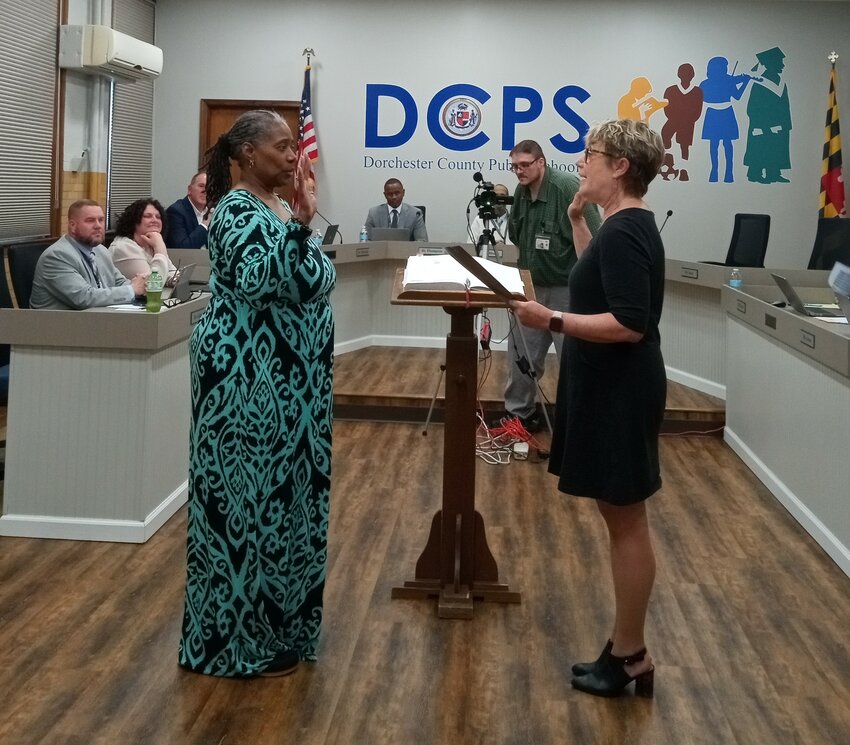

Dorchester County Council recently appointed her to fill the remaining school board term of the late Dr. Theresa Stafford, who passed away in December 2023, representing District 2.

And on …

DUNDALK, Md.— More than 1,000 small businesses have sought emergency federal loans to stay afloat following the March 26 collapse of the Francis Scott Key Bridge and closure of much of the Port …

SALISBURY — MAC’s 2024 Virtual Alzheimer’s and Dementia Caregivers Conference, “Dementia: Navigating the Journey,” will be held Wednesday, April 24. CEU registration …

E-Edition

View this issue of Dorchester Banner or browse other issues.

Sports

CAMBRIDGE – At Cambridge-South Dorchester High School’s home meet April 10, the men earned a win, with a score of 160.5 points. They were followed by Parkside, 67; James M. Bennett, 55.5; …

SHILOH – On April 10, the North Dorchester High School Boys’ Track and Field Team won their meet against Colonel Richardson, Crisfield and Washington with a score of 87.5. Results are …

Over a decade ago Kylie Curtis’ dream of playing soccer at Crisfield High School was nearly impeded by one major obstacle: there was no girls’ team.

The 2012 graduate was 10 years …

Business

Business Insights

CAMBRIDGE – On March 22, U.S. Senator Chris Van Hollen (D-Md.) visited J.M. Clayton Seafood Company to meet with local crab house representatives and discuss efforts to support …

Three Hundred and Fifty Dorchester County Chamber of Commerce members gathered to wine, dine, and be inspired at the Hyatt lChesapeake Thursday, March 21 from 5 to 9 p.m.

The 78th Annual Membership Meeting and Dinner attendees represented a crossroads of the local community. State, County, Cambridge, and Hurlock officials were on hand. So, too, were those from the ranks of large and small businesses, agriculture, service organizations, and the nonprofit community.

Business Insights

The basics of producing corn, soybean, and wheat crops aren’t rocket science to local growers. It’s a way of life, day in and day out, sunup to sundown, year after year.

Cambridge

CAMBRIDGE -- Almost two years after becoming Cambridge City Manager in April 2022, Tom Carroll submitted his resignation due to differences over the direction of the Cambridge Harbor waterfront development project.

ANNAPOLIS — Lawmakers are moving toward consensus on changes to Maryland’s juvenile justice system, discussing how to address crime by children ages 10 to 12 and get them into …

ANNAPOLIS — Maryland’s Democratic-led legislature passed the Blueprint for Maryland’s Future in 2021, vowing to pour billions of dollars into the state’s public schools to …

CAMBRIDGE – If Dorchester County had a Boat Builders Hall of Fame, Neck District natives Captain Jim Richardson and Harold Ruark could have been picked.

These local legends’ legacies …

Neighbors

CAMBRIDGE – Both the Cambridge and Hurlock branches of the Dorchester County Public Library were scheduled to be closed April 16 for a Professional Development Day. We are focusing on …

“Zeta is a verb, as we are a community conscious, action-oriented sisterhood” – Iota Chi Zeta chapter

The Eastern Shore’s single chapter of historic, international …

CAMBRIDGE – Before we get to sharing our exciting upcoming events schedule with you, here’s a quick reminder about our updated hours of operation at the Cambridge Branch …

Things to Do

‘Joy Through Art’ is Main Street Gallery’s spring show

CAMBRIDGE – Main Street Gallery is excited to be exhibiting the artwork of Joy Staniforth as its guest artist for the May/June …

Cambridge Community Garden starts ninth season April 27

Behind historic Waugh Chapel AME Church on High Street, an urban oasis of greenery and neighborly spirit has been flourishing since …

Get eclipse eyewear for free at Dorchester County Public Library

Protective eyewear is available for viewing the eclipse on Monday, April 8, free to the public at both the Cambridge Branch at 303 Gay …

More Things to Do

Schools

CAMBRIDGE – The Dorchester County Public Schools Board of Education announced last week that as part of the process to select the next superintendent of schools, there will be a series of …

CAMBRIDGE – From March 21-24, the Cambridge-South Dorchester High School Theater Department delighted audiences and demonstrated that musical theater is alive and well with their performances …

Katelyn Robinson, a pre-kindergarten teacher at Maple Elementary School, has been named the Dorchester County Public Schools Teacher of the Year for 2024-2025.

A graduate of Cambridge-South …

Opinion

The members of the Maryland-Delaware-DC Press Association are deeply concerned about the potential consequences of Maryland House Bill 1258 on local journalism.

I am a concerned Ocean Pines, Maryland, citizen who is appalled by the unsightly litter along our roads and waterways in our otherwise beautiful Eastern Shore. It’s time to actually do something to deal with this issue.

The Alabama Supreme Court, citing Dobbs v. Jackson Women's Health Organization, has ruled that the frozen embryos used in IVF (in vitro fertilization) are children and entitled to all the protections …

Last week's Viewpoint page featured an open letter submitted by the Maryland House Republican Caucus expressing their concerns that a juvenile sex offender convicted of second-degree rape …

As Cambridge Waterfront Development, Inc. (CWDI) advances its mission to develop Cambridge Harbor, we plan to keep the public informed on our progress and what you can look forward to in the coming …

When the opening day of the 2024 Maryland General Assembly session was called to order, Delegate Sheree Sample-Hughes was the speaker pro tempore in the Maryland House of Delegates, the second-highest position for a member of the House Democratic Caucus.